Precision Fabrication Machinery Kansas City

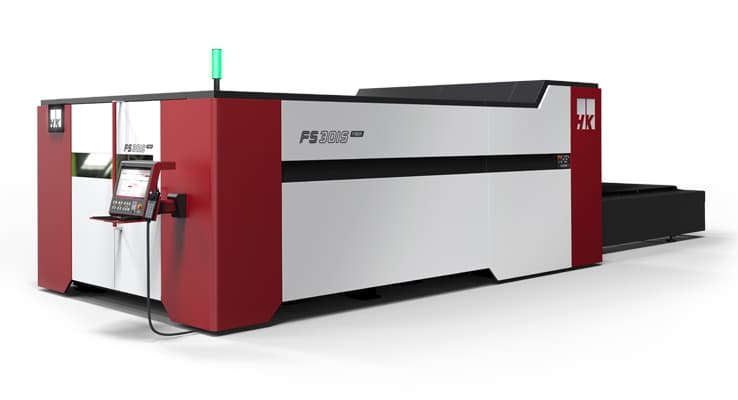

Our focus is on high-end equipment designed for high-end uses. We are committed to delivering custom-fabricated components, equipment, and equipment that works under pressure. Check out our precision solutions.

Gulf States Saw & Machine Co. offers CNC machining services. GSS Machinery is available to help, regardless of whether your requirements are 2D or 3.